Overview

There's no long classroom sessions here. After introducing PDCA (Plan-Do-Check-Action) and a safety briefing you will spend the remainder of your time on the shop floor. Lines can not be effectively managed from the comfort of a chair in the office so the fact that this course spends so much time on the Gemba should not come as a surprise.

Small groups gain access to the heart of Toyota production to see how our supervisors set shifts up to succeed, problem solve on a daily basis and deploy continuous improvement such that every shift is better than the previous one.

Key study areas

- The level of personal commitment required from a leader.

- The need for Gemba and real shop floor observation

- The PDCA cycle

- Fact based decision making

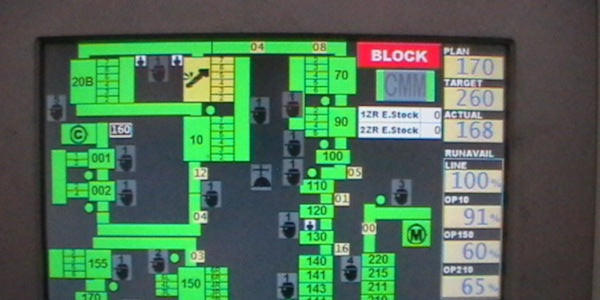

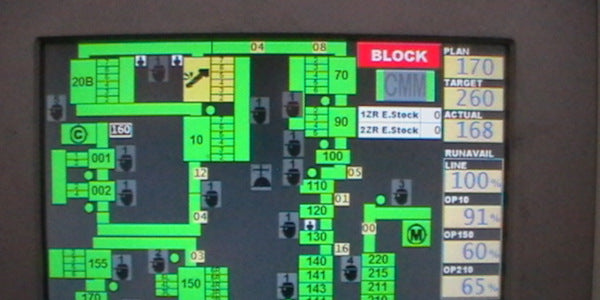

- Visual management tools & techniques

- Management kamishibai

- The power of positive confirmation

- Effective use of Andon

Aimed at

All Supervisors and Managers with leadership responsibility

Course Information

We want to show you how things are done here at Toyota. This course can therefore only be delivered at one of our manufacturing plants, courses are offered at both Burnaston and Deeside.

With the exception of a few short breaks you'll be on your feet and walking until the day finishes. We'll provide coffee breaks and a lunch but expect to be exhausted.

£480+VAT per person.

Customer Comments

"My legs are tired! You challenged me to take one idea away but I'm leaving with too many to count. I think all my colleagues should do this course."

"Open and engaging presenters. Shop floor incite was most insightful as we saw TPS in the 'real world'."

Course Etiquette

Courses can contain participants from several organisations. Conduct should be professional to ensure that all participants are able to enjoy the course.