Background

The Guide Dogs for the Blind Association exists to provide life-changing services to the 360,000 people who are registered blind or partially-sighted in the UK, with the aim of supporting the further two million in the UK living with sight loss. TLMC were invited to visit the national workshop as part of Toyota's corporate fundraising and we met a team of people with an incredible customer focus. With this shared value we set about looking for ways TPS could be used to help.

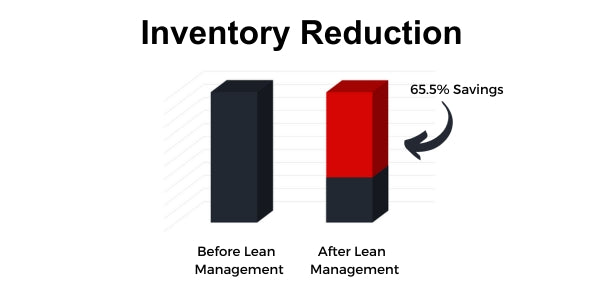

Inventory Reduction

Approach

Toyota's Visit to the Harness Workshop

The Toyota team reviewed every aspect of the production and distribution of Guide Dogs’ harnesses. They observed that good ‘kaizen’ principles are being used, with a recent reduction in the amount of time it takes to produce 30 harnesses from 653 to 609 minutes. However, they discovered a high level of inventory owing to a ‘just in case’ principle.

After this initial review we decided that the "Just in Time" pillar of TPS and specifically "pull and fill up" could be applied to reduce inventory. Not only freeing up valuable cash this allowed for better visual management and maintained confidence that a client would never be kept waiting for equipment.

Results

Pull System and Reduced Inventory

Compared to the starting condition the inventory was reduced by 66%. Lean doesn't mean no inventory it means appropriate inventory. In fact in some instances additional product was needed. Having the appropriate inventory and a kanban system which provides visual control means the workshop can continue to offer equipment within 24 hours, which is important because a guide dog without a harness cannot offer the vital support clients rely on. The £14,000 reduction in inventory can be used to improve lives.

Find out more about the work of Guide Dogs for the Blind Association

Contact

Interested in finding out more?

If you want to discuss your needs with Toyota Lean Management centre, please fill in the form, call or email us

tmuk.tlmc@toyotauk.com

+44 (0)1244 282 135

Toyota Lean Management Centre

Toyota Motor Manufacturing (UK) Ltd

Deeside Industrial Park

Deeside

Flintshire

CH5 2TW

Our most popular courses

Our Services

In today’s highly competitive society, Lean management training has never been more important

Diagnostics

Toyota Lean Management Centre will visit your site for an in-depth study to benchmark your organisation against TPS and The Toyota Way.

Available for both manufacturing and service companies.

Understanding the culture of your organisation and how Lean tools are currently applied will enable us to propose an action plan tailored to your business.