The Opportunity

Toyota Lean Clusters Programme

The Welsh Government and the Toyota Lean Management Centre, Deeside, have collaborated to offer businesses in Wales a unique opportunity to achieve sustainable improvements in competitiveness.

The programme aims to bring measurable improvements in productivity, through the sharing and coaching of lean management principles.

Delivered by experienced Toyota practitioners, participants will receive a mixture of:

- Classroom theory

- Immersive shop floor observation

- Examples of practical application all delivered at Toyota’s Deeside engine facility

- Worksite coaching at participant company sites to support productivity improvements

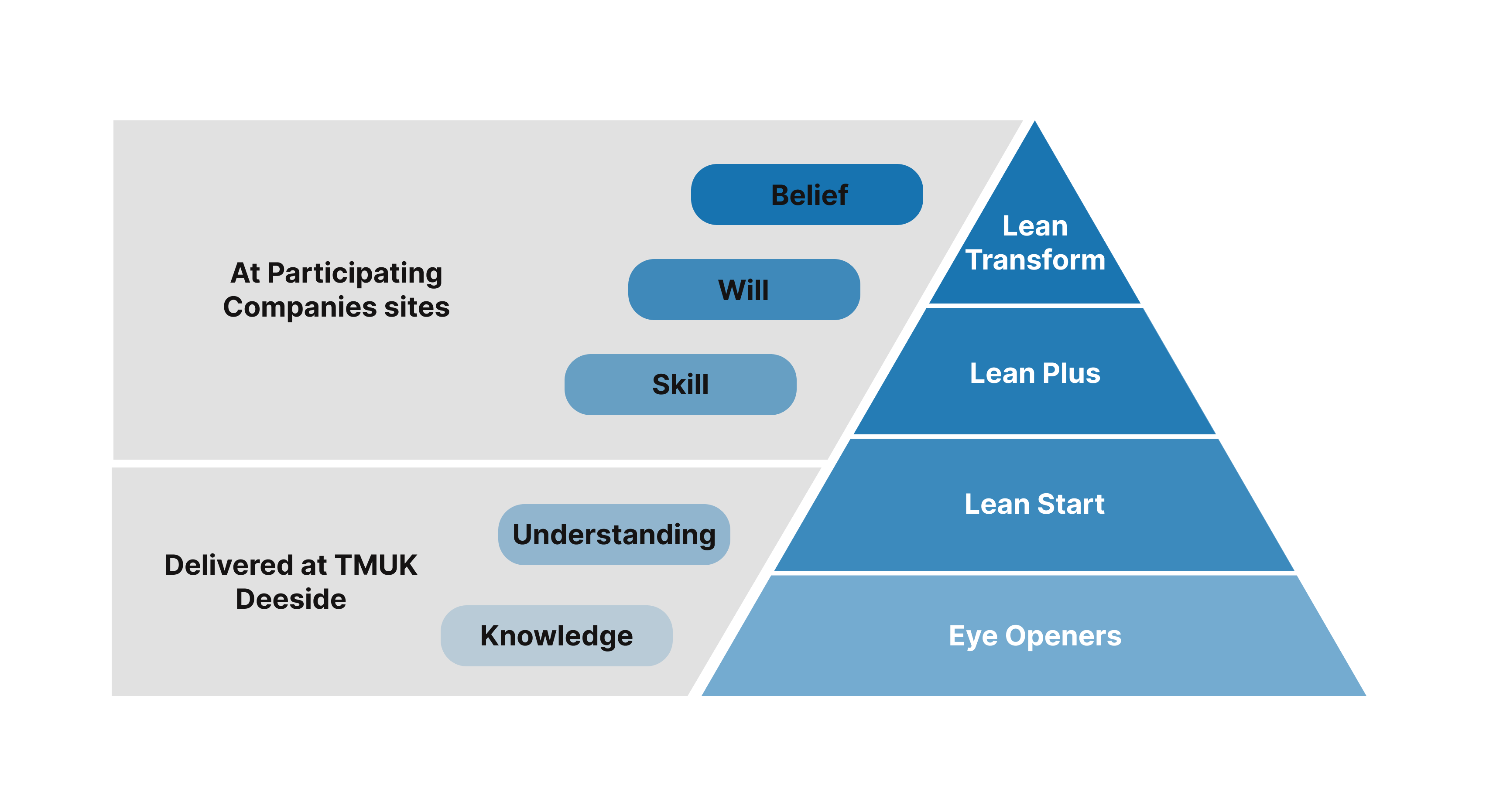

Flexible programmes to suit your business

Options

Developing a lean culture

Rototherm

Rototherm, a company seeking to expand its production, implemented Lean Start to streamline operations and meet growing demand.

Key Achievements:

- Established a robust production structure for high-growth.

- Enhanced problem-solving capabilities.

- Created standard procedures for new technology production.

- Implemented a KPI tracking system for data-driven decision making.

- Scaled up production by 5X.

- Achieved a 300% increase in outputs and a 50% decrease in defects.

- Improved team morale and leadership effectiveness.

Looking ahead: Rototherm plans to continue its Lean journey by participating in the Toyota Lean Clusters, Lean Plus program.

Workplace Organisation

Fitzgerald Plant Services Ltd

Fitzgerald Plant Services, implemented Lean Start to improve efficiency.

Key Achievements:

- Reduced defects through data analysis and staff training.

- Standardized work processes with SOPs (Standard Operating Procedures).

- Improved data-driven decision making with daily data collection and analysis.

- Achieved a 67% increase in capacity.

- Higher production rates, better resource control, and improved workshop morale.

- Implemented a 5S workplace organization system.

- Established a culture of continuous improvement.

Changeover Improvement (SMED)

Airflo fishing products ltd

Airflo, a manufacturer of high-quality, fishing products, implemented Lean Start Project to improve production efficiency. This resulted in a reduction in time and material waste and an increase in production. Key achievements include:

- Created a new standardised changeover procedure with visual instructions

- Implemented SOPs (Standard operating procedures) for production

- Trained operators on the new procedures

- Achieved time saving of 170 minutes per day

- Increased production by 113 lines per day

- Generated additional revenue of up to £544,000 per annum

Contact

Interested in finding out more?

If you want to discuss your needs with Toyota Lean Management centre, please fill in the form, call or email us

tmuk.tlmc@toyotauk.com

+44 (0)1244 282 135

Toyota Lean Management Centre

Toyota Motor Manufacturing (UK) Ltd

Deeside Industrial Park

Deeside

Flintshire

CH5 2TW