Overview

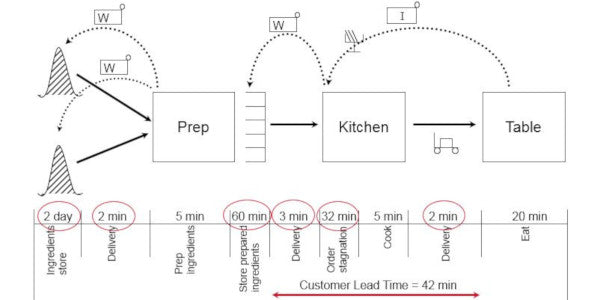

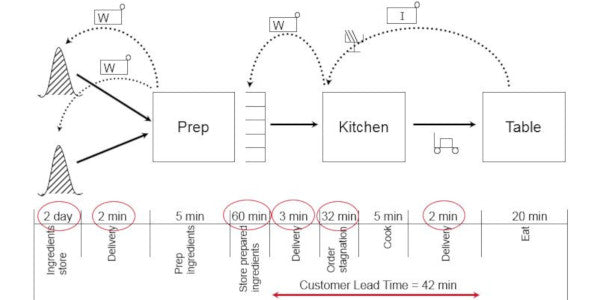

A tool for process visualisation and lead time reduction. Value Stream Mapping (VSM) is a tool for visualising the flow of material and information within a process and quite often will be referred to as Material & Information Flow (M&I) within Toyota.

If you can imagine your business as a timeline that starts from the point when you get the order and ends at the point you collect the cash then what we are trying to do is reduce that timeline by eliminating non-value added activities within it.

VSM training from Toyota enables you to visualise the timeline and grasp the opportunities. It can be used to understand both the current state and as a tool to visualise the desired future state of any process.

Key VSM Training Areas

- The purpose of value stream mapping

- How to study the process and recognise all points of stagnation

- Establish targets for future state conditions

- Develop and implement an improvement action plan

Aimed At

All levels and areas within an organisation

VSM Course Information

This course can be delivered either at our Deeside Engine Plant, Burnaston Car Plant or at your own site. After a short classroom session, we want to spend most of the day on the Gemba. Holding the course at your own site means participants study your own process and the team will generate a VSM and kaizen plan which will provide real benefits to your organisation.

Course duration is one day with the start time flexible to suit your requirements.

£480+VAT per person.

Course Etiquette

Courses can contain participants from several organisations. Conduct should be professional to ensure that all participants are able to enjoy the course.