Overview

Delegates will, through the use of simulation techniques, extensive worksite study and classroom presentation, grasp the meaning of key elements of TPS and gain appreciation of its practical application. They will understand the culture and performance management tools that exist in order to ensure TPS can be sustained and provide the highest levels of operational performance.

Delegates will also understand the process steps for implementation and their role in leading a Lean Transformation.

Key Study Areas

- Toyota Philosophy & Basic Thinking

- A Customer Driven Focus

- Continuous Improvement & 7 Wastes

- Shifting Sands or Solid Ground – Importance of Stability

- TPS Overview

- Continuous Flow Process & Jidoka - Built in Quality

- Standardisation - The Foundation

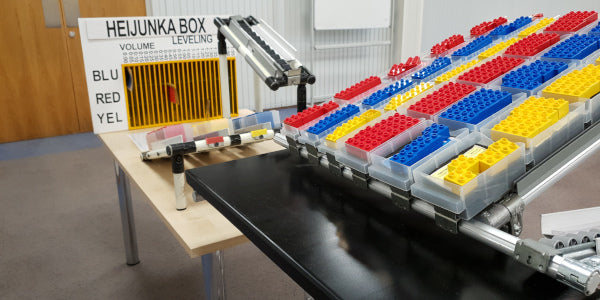

- Production Planning & Pull System

- Human Resources for a Lean Environment

Aimed At

All Management & Lean transformation leaders.

Maximum of 18 delegates on each course.

Course Information

Viewing Lean in action at our state of the art manufacturing facilities is an integral part of this course. This course is therefore only available at either our Deeside Engine Plant or Burnaston Car Plant.

We start at 08:30 on both days. Day 1 runs until 16:30 after which instructors will meet you for a meal at 18:00. On day two you will finish at 13:00.

£860+VAT per delegate.

Customer Comments

"Very thorough knowledge base with inspiring translation to the shop floor."

"Great content and very relevant to my job. Personable and knowledgeable instructors created a relaxed but professional atmosphere."

"I loved everything about it!"

"Excellent course, training and presenters. Entirely believable!! Will be a huge help to me in my organisation"

Course Etiquette

Courses can contain participants from several organisations. Conduct should be professional to ensure that all participants are able to enjoy the course.